The it's technically still Wednesday update

Except not anymore, Bar posted this late last night to Kickstarter and I’m sending it out this morning! -Anna

Happy Wednesday Everyone!

It's technically still Wednesday for another 30 minutes so we're not late :p. We've been burning the midnight oil helping forums member @Azab2c get ready to head to Open Sauce with his Maslow. We also made an excellent discovery about the stability bug that we've been hunting in the process, but more on that later.

We applied to take Maslow to Open Sauce this year, but we didn't get accepted...well technically we got invited to be a corporate sponsor, but we absolutely can't remotely afford that so we resigned ourselves to not going. Then forums member @Azab2c who is here in Seattle also reached out to let us know that he is going along with some of his projects and asked if we would help him get his Maslow in shape to show.

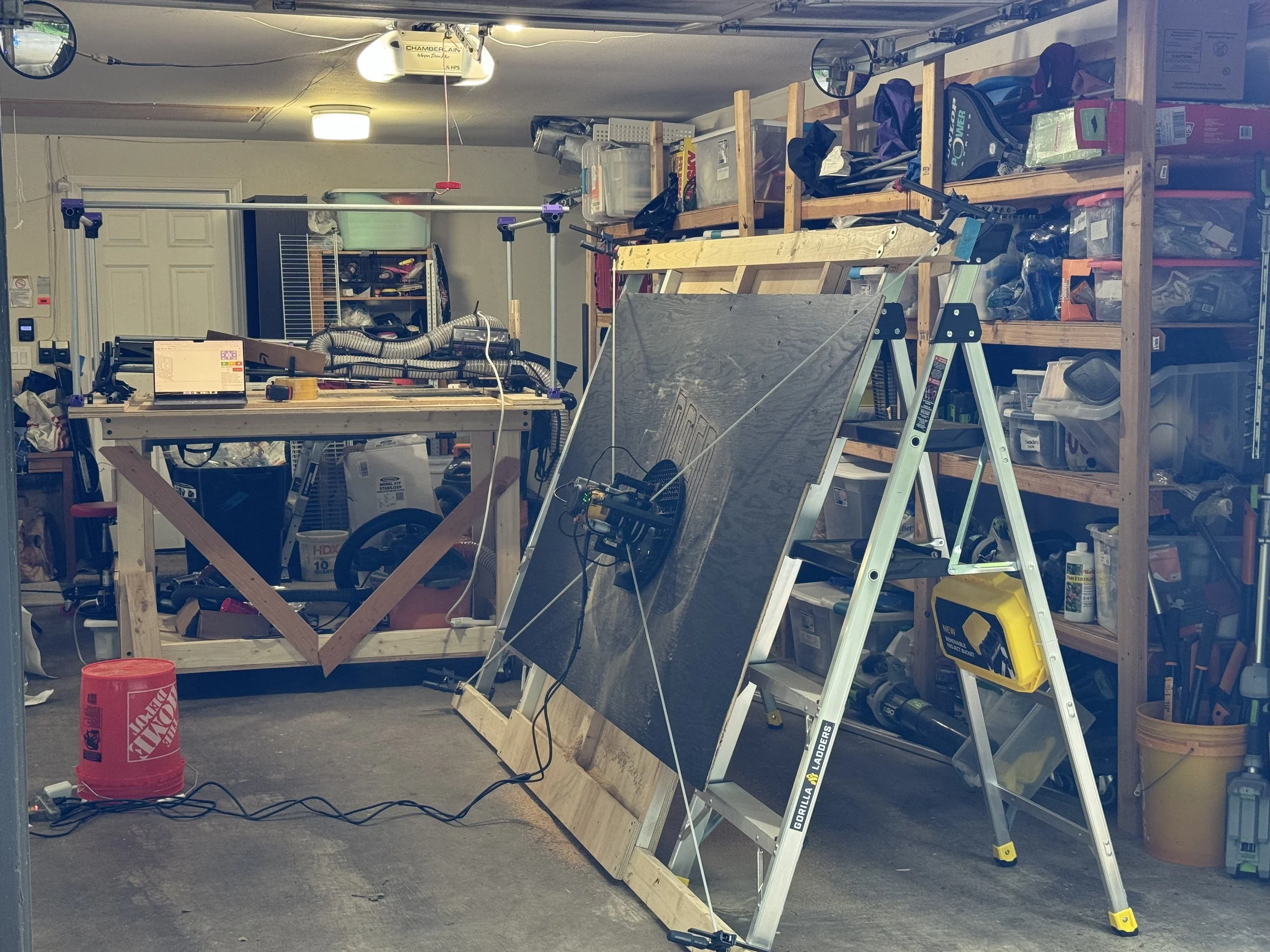

He had a really cool idea to build the frame using some aluminum ladders to make it collapsible which worked out great. It's not a full size frame, but for demonstration purposes it's great. We also got to test out the idea of using C clamps as the anchor points and that also worked quite well.

It's super fun to have an excuse to try new things and push the envelope. We decided to cut some signs that says “Open Sauce”. He’s leaving later tonight so it had to happen NOW.

We started cutting the sign and BOOM right away get the error we've been tracking down where the ESP crashed, we didn't even make it half way through the O in “Open Sauce”

I’m like **** this didn’t used to happen…how can I fix this issue in the next hour? Then it hits me…this didn’t used to happen! If it didn't used to happen then what's changed? The firmware version! I thought maybe going back to an earlier version could fix it so I jumped all the way back to firmware version 0.64 and everything cut normally.

Does that mean that you should go back to 0.64 if you are having that issue? No. 0.64 is horrible. We’ve made so many improvements since then.

What it does mean is that we (being Anna and I) need to go through and test each firmware version to figure out where the issue started appearing and then track down why. It might take us a little bit, but we’re on it! It feels good to be making progress on tracking down where that issue came from and we couldn't have done it without @Azab2c giving us an excuse to try something new and step out of our comfort zone.

Firmware Updates

This weeks weekly update contains a number of small fixes and improvements.

Thanks to @ronlawrence3 we are now able to properly rename folders on the machine which fixes a bug that it was impossible to delete a folder named index.html.gz if you were to upload one accidentally. @md8n fixed some printing of warnings to use the correct format, and fixed an over current error message that could pop up while running take slack.

We're still hard at work tracking down the bug that is causing the ESP32 to crash on long cuts, but we're making progress on multiple fronts there.

You can find 0.77 here.

Highlights from the Forums

Forums user @Bob_Craig made a really great sign for his friend. He also included a great tip in his post about marking the X-Y home with the bit before starting a cut so that if you have to pause the cut, or take down your machine, you can set it up again and check that the x-y home is the same before resuming your cut. An excellent suggestion, just remember to make this mark outside of your cut area so that it ends up on a scrap piece.

Forums user @boxomatic has designed a stand that can fit inside a Festool carrying case and also double as a maintenance stand. Check it out here!

Forums user @VetterTech decided to upgrade their heatsinks to handle hotter work environments. They also used thermal tape to ensure there is no barrier preventing heat transfer from the chips.

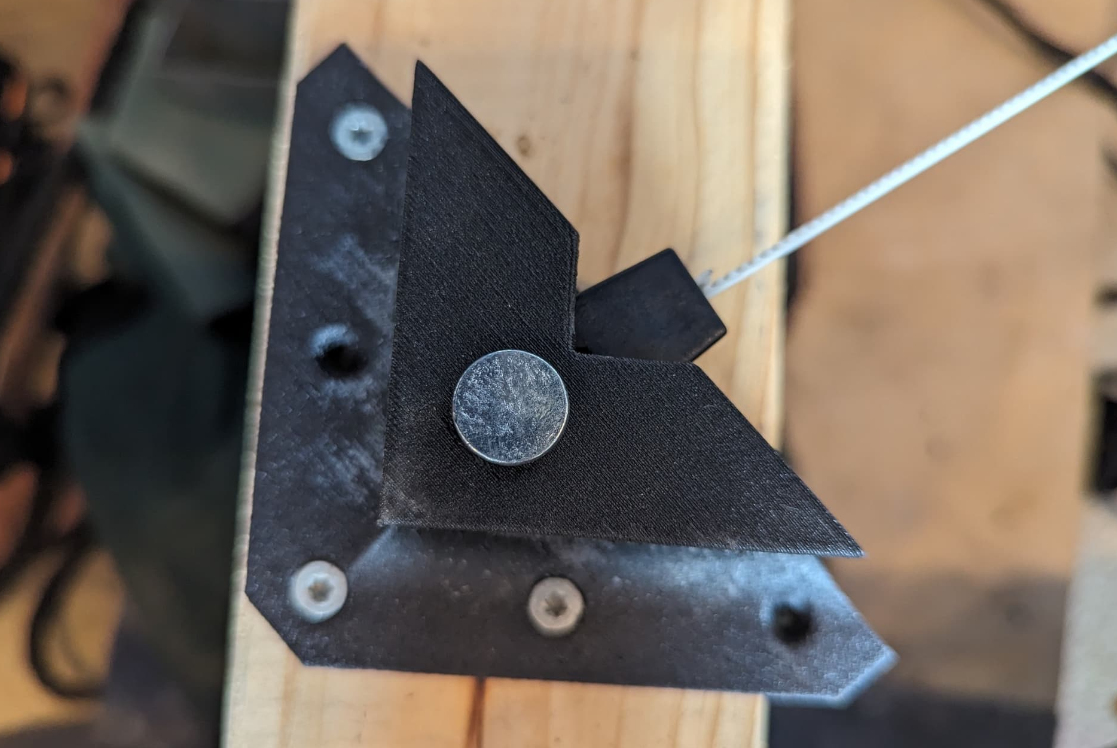

Forums user @E_L_P took the initiative to improve the 3D printing file for the corner anchor point. They changed the orientation of the part so that it doesn’t need supports while printing and improved the countersink for the screws. Great work!

Last but not least, Forums user @md8n modified their machine to use a spindle instead of a router. Check out their process here. Their build includes a 2 part sleeve to increase airflow and allow the spindle to be swapped.

Anna has been running tests at ALTSpace and was able to cut super close to the edge of the plywood, about 2 cm, without the sled tipping.

That’s all we have for this week. It’s really fantastic to see everyone’s projects come together as they get up and building! Remember to post your projects and ask questions in the forums. Something you are working on may help someone else.

Have a good week!

-Bar , Roman and Anna